Time:10 AM onwards

Venue: Industrial Area, Baikampady, Mangaluru

Beneficiaries: I MBA Students

On 30th July, 2024, the first year MBA students from St. Agnes College (Autonomous), Mangaluru undertook an Industrial Visit to three prominent industries located in the Baikampady Industrial Area, Mangaluru. This visit aimed to provide students with practical exposure to the industrial environment and operational practices complementing their theoretical knowledge with real-world applications.

A total of 57 students participated in this educational excursion. The visit was meticulously organized and accompanied by our esteemed staff coordinators, Ms. Arlene Fernandes and Mr. Chaco PJ, who ensured a smooth and informative experience throughout the day. The journey commenced at 10:00 AM as we departed from the college premises. The industrial area of Baikampady, Mangaluru, known for its diverse manufacturing units served as an ideal location for our academic exploration. The visit concluded with our return to the college at 4:00 PM.

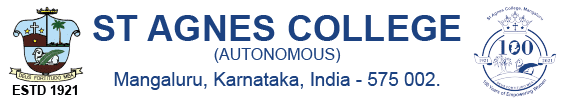

Gurucharan Industries

Our first stop was Gurucharan Industries, established in 1996 and now a prominent player in the manufacturing sector for 28 years. The industry employs between 120 to 150 staff members and boasts a wide range of machinery valued between 11 lakhs to 3.5 crores. Gurucharan Industries specializes in producing various types of bags including carry bags, milk packs and courier bags. One of the standout features of this industry is its commitment to sustainability as they reprocess waste instead of disposing of it.

During the visit, we were guided by Mr. Kadir, who provided a comprehensive overview of the operations and safety measures in place. Notably, Mr. Kadir also treated us to ice cream at the end of the visit adding a delightful touch to our experience.

We also observed the safety measures implemented to ensure worker safety. Staff members are equipped with helmets, masks, and gloves. Additionally, the industry prioritizes the health of its employees by providing health camps every three months. The visit provided valuable insights into the integration of advanced machinery, sustainable practices and comprehensive employee welfare programs in a manufacturing setup.

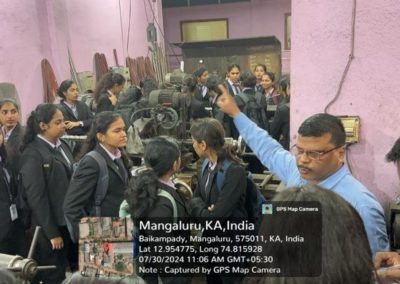

Vinayaka Engineering Works

Vinayaka Engineering Works was founded in 1986 and has grown steadily gaining a reputation for quality and innovation. It is an IBR approved special class boiler repairer, package and small industrial boiler manufacturer. They manufacture wide range of products for process heating, cashew processing industries food processing units, refrigeration plants, laundries and rice mills.

We visited one of its cashew processing machine manufacturing units. The company’s staff representative Mr. Sanjay Kumar provided informative session outlining the history, mission, and the strength of the company. They increase their profit margin by selling their products to all over India as well as exporting to countries like Benin, Africa, Indonesia, and Sri Lanka.

Students observed each stage of manufacturing which gave valuable insight to understand modern technologies, hands on experience, lean manufacturing principles and safety protocols that company follows. They also gained information regarding entire production process from raw cashew nut arrival to final packaging and insights into the various stages involved including shelling. roasting, grading and packaging.

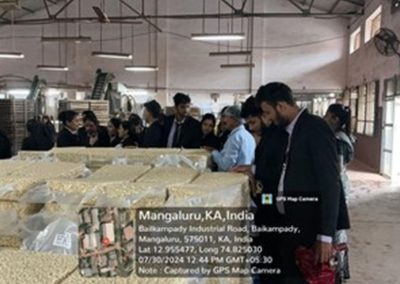

Achal Cashew Industry

The final stop on our visit was Achal Cashew Industry, established in 1981 and holding ISO 840 certification. Achal Industry operates as an exporter, manufacturer and supplier, known for its specialization in cashew processing. Mrs. Malika and Mr. Anand Devadiga our knowledgeable guides at Achal Industry provided a comprehensive tour of their operations. They explained that Achal Industry sources raw cashews from external suppliers and focuses exclusively on the peeling and packaging processes.

We saw how the cashews were moved to the next stage, where they were flavoured and packaged. It was a first-hand experience to see how the industry adds various flavours to the cashews, enhancing their appeal and value. The packaging process involved creating packets in a range of sizes from grams to kilograms, to meet both local and international market requirements.

Mrs. Malika and Mr. Anand Devadiga elaborated on the meticulous techniques involved in cashew peeling ensuring quality and consistency in the final product. The packaging section highlighted the critical role of proper packaging in maintaining product freshness and extending shelf life. This segment of the visit was particularly enlightening showcasing the intersection of traditional practices with modern technology.

The Industrial Visit to Gurucharan Industries, Vinayaka Engineering Works and Achal Cashew Industry was a highly enriching experience for all participating MBA students. It provided an invaluable opportunity to witness firsthand the operational aspects and management strategies employed by successful industrial units. The knowledge gained through this visit will undoubtedly contribute to our academic growth and future professional endeavours.

This experience has broadened our understanding of industrial processes and inspired us to apply our theoretical knowledge in real-world scenarios.